Our campus infrastructure has evolved from individual fireplaces at the turn of the 20th century to a sophisticated natural-gas-powered co-generation system commissioned in 2009,12 transforming over time to more efficiently, cleanly and safely meet the needs of the campus. As we enter our third century, we will transform our campus energy system away from fossil fuels to renewably sourced energy to meet our goal of carbon neutrality and take action against climate change.

The Climate Action Task Force hired the consulting firm Integral Group to determine the technical and financial viability of this transformation. To complete this task, Integral modeled the energy systems on campus, developing an in-depth understanding of the heating, cooling and electrical demands of our infrastructure. Before proposing the transition adopted by this plan, they considered whether bio-based fuels, carbon capture and storage, or offsets would be viable alternative methods for reaching carbon neutrality. None of those options were suited to meet the goals of the College as well as energy system transformation, summarized in Figure 4.

| Energy Source | Heat Distribution | Low/Zero Carbon Options | |

|---|---|---|---|

| Current | Natural Gas Co-Generation | Steam | Biomass, liquid biofules* |

| Future | Air and ground sources moved by an electric heat pump | Hot Water | Renewable electricity |

*Uncertainties about forest growth equilibrium, liquid biofuel available, cost

Figure 4: Current and Future Energy Sources and Thermal Media

The following list of actions serves as a summary of the transition; you can also read the full Integral Group report on our Zero Carbon Energy System Study page.

Action: Transition the campus’s heating and cooling systems from steam to low-temperature hot water

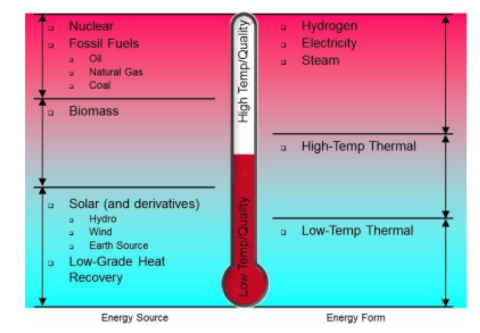

Co-generation provides a large improvement over a traditional plant by creating steam and electricity at twice the efficiency, but the fundamental problem is creating steam, a process that requires high-energy-content fuel (Figure 5).

Figure 5: High-Energy-Content versus Low-Energy-Content Sources and Forms (Integral Group, 2017)

While biomass and bio-based liquid fuels can also create steam, the amount required to meet our current infrastructure needs—along with the reduced efficiency, sourcing challenges and environmental tradeoffs of biomass feedstocks—does not make fuel-switching a viable option. Bio-based fuels may be the best choice to meet peak load demand13 or other periodic uses, but it is not possible, with the current infrastructure, to decarbonize our campus by switching from a fossil-based system to one that fully utilizes renewable fuels.

The good news is that steam is not required to meet our heating needs. District hot water systems, popular in many European cities, use low-temperature water (typically 120 degrees) to provide heat. Heating water to this temperature requires less energy than producing steam, and water can be transported safely and with less maintenance than steam, but most importantly it can be heated through many low-carbon and carbon-free sources.

Achieving the transition from steam to low-temperature hot water will require new piping infrastructure around campus. Our newest buildings, such as the Greenway Dorms and Science Center, have been built to accept low-temperature hot water heating. We will need to update our other buildings that currently operate on steam-fed heating systems.

Action: Create low-temperature hot water through ground-source heat pumps

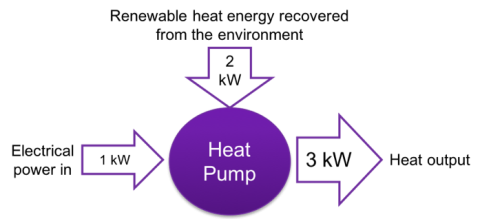

The Integral Group analysis determined that the thermal load of our campus can be met with a low-temperature hot water system powered by ground-source heat pumps. These pumps take low-temperature renewable heat energy recovered from the environment and use electricity to increase, or lift, the heat value of the energy. Heat pumps can also be used as chillers, moving warmer air out of a building to be cooled with low temperature renewable heat energy (Figure 6).

Figure 6: Heat Pump/Heat Recovery Chiller Energy Flow

Specially, water will flow through a closed loop system into geothermal wells, where the water’s temperature will become equal to the constant temperature of the earth, between 50 and 60 degrees Fahrenheit. The water will then be sent through a heat pump that uses electricity to lift the temperature up to an additional 90 degrees F, allowing that water to be used in a low-temperature hot water heating system. Once it heats the space, the water will be sent back through the geothermal system to reject its heat and return to the starting temperature of 50–60 degrees F. These systems are designed to ensure that the temperature of the ground is not affected by the rejection and withdrawal of renewable heat energy. At Amherst, we will need to install a solar thermal heating system to introduce some extra heat energy into the system to avoid ground cooling. In addition to learning from peer institutions that have used this technology, we have local experience at the Inn at Boltwood, where a ground-source heat pump low-temperature water heating and cooling system was installed during its renovation in 2012.

To do this on campus, we will need a geothermal well field and heat pumps. The Integral Group analysis assumed a geothermal well field under Hitchcock Field, although the final design may include wells in other locations to minimize disruption to field uses. There are also multiple options for heat pump design. We could develop a centralized heat pump plant that serves all of campus, or have heat pumps in different buildings around campus, creating a district effect. Some options were considered in the Integral Report, but the next phase of analysis will require more details considering the disruption, resiliency and cost of these different possibilities.

Action: Procure zero-emission renewable electricity to meet all our heating, cooling and electrical needs

By moving to a ground-source heat pump system, we can meet the thermal load of our campus through renewable energy from the ground and electricity. To meet our carbon neutrality goal, we need to complete the transition and procure zero-carbon renewable electricity.

Although we currently create electricity in our co-generation system, we also purchase around half of our annual electricity from the grid. Therefore, the task force identified procurement of renewable electricity as an early action we could take to reduce our emissions. In April 2018, we announced a partnership with several peer institutions to contract a total of 76.5 MW of energy from a new solar panel installation in Farmington, Maine, set to come online in early 2020.14 We contracted 10,000 MWh per year for a 20-year term, which covers nearly all of our currently purchased power. However, as we move to electrify campus and decommission the co-generation system, we will need to purchase significantly more electricity.

To achieve this, we will first need to understand how much renewable power we can generate on campus, exploring different types of ownership and financing models. Then we will likely need to look into similar contract arrangements to the one we have in Farmington. Energy storage will also be key in helping us reduce peak load demands, saving money and reducing the need for backup combustion systems. Battery storage from solar systems and thermal storage will need to be explored in more detail.

Action: Reduce our energy load and reap greater benefits from our new energy system

Energy efficiency has been a key design feature in our new buildings and significant retrofits for over a decade. Newer buildings that have pushed the envelope on their energy-efficient designs, such as the Greenway Dorms and Science Center, include complex technologies that require sophisticated operating procedures. This level of complexity will only continue as we move toward a decarbonized infrastructure. While, on the surface, energy conservation may seem less important when operating a low- or zero-carbon building, reducing energy demands is critical for utilizing low-energy heat pump technologies, reducing peak loads and maximizing the sources available on campus. Unfortunately, analysis has shown that more complex mechanical systems can sometimes lead to more energy use due to the addition of more components (e.g., central cooling) and operational errors.15

Ensuring our infrastructure is operating as designed will require continuous commissioning to quickly identify operating abnormalities; funding streams to implement projects that replace, repair or improve upon our building equipment; and strong and consistent communication to the building occupants on the importance of energy conservation. We have already taken action on many of these: we have hired additional Facilities staff to operate the Science Center, invested in energy meters in campus buildings to better identify energy conservation projects and track their impacts, and begun using a green revolving fund to support energy-efficiency projects around campus. We must continue to increase energy-efficiency in new and renovated buildings.

Financial Analysis

In addition to considering technical feasibility, Integral Group was asked to do a high-level assessment to determine the financial feasibility of an energy system transformation. The details are outlined in section 6 of the Integral Report. (Read the full Integral Group report on our Zero Carbon Energy System Study page.)

In summary, significant operational cost savings from “business as usual” (BAU) will be achieved by transitioning away from our current energy infrastructure to a “no-carbon option” (NCO). Those savings can be applied to offset a portion of the capital costs of the system. Operational cost savings result from a reduction in the supplementary energy we will have to purchase after using “free” ground-sourced heat energy; from savings in steam loss; and from heat recovery during “shoulder seasons” when we are simultaneously heating and cooling different buildings around campus. While capital costs for the BAU case are lower than the NCO, it is worth noting that under BAU, the power plant, which is more than 45 years old, would require significant capital investment in 10–15 years to replace systems that reach their end of life. BAU will not allow us to achieve carbon neutrality, and it exposes us to additional risks from regulatory changes like carbon taxes and fuel cost volatility.

12 Co-generation is a technology that captures waste heat from electricity generation to create steam. By using this technology, the College was able to increase the efficiency of the power plant by more than 50 percent, allowing us to meet our demand with less fuel and lower GHG emissions.

13 Peak load demand is the highest heating, cooling or electricity load needed during a certain season or event. For example, on very cold days, ground-source heat pumps may need to be supplemented with combustion-based boilers to ensure heating demands are met.

14 https://www.amherst.edu/news/news_releases/2018/4-2018/bulk-buying-the-sun

15 “State of Sustainability in Higher Education 2017: Trends in Climate Change Mitigation and Adaptation.” Sightlines and University of New Hampshire, 2017.