Shipping and Packaging - Dry Ice

April 2022

Introduction

Both the Department of Transportation (DOT) and the International Civil Aviation Organization and the Federal Aviation Administration (ICAO/ FAA) regulate shipments of dry ice as it is considered a hazardous material because of the potential for asphyxiation.

Regulatory requirements, including package compliant protocols and mandatory training are of significant importance. Amherst College faculty and staff must follow the procedures and requirements identified below, as it pertains to packaging and shipping with Dry Ice, regardless of quantity. Failure to comply with these rules and regulations can result in substancial fines from the DOT and IATA.

It is absolutely essential that person(s) who ship (including returns) a package from Amherst College, follow and understand the significant differences between shipping with Dry Ice and shipping an IATA regulated package.

Packages refrigerated with dry ice are normally shipped by air in order to reach their destinations quickly. Information in this guide pertain to shipments of Dry Ice only. If a package must be sent out by a carrier (DSL, Fed-Ex, UPS etc...) that contains any chemical (dry, gas or liquid), biological or botanical sample, tool or piece of equipment that is battery powered, requires the person shipping the package to be trained, or request the services of an Amherst College IATA / Dry Ice authorized faculty or staff member. Failure to comply with the above referenced requirements for dry ice and/or IATA shipments will result in a fine of $50,000 and Notices of Non-Compliance from the state and federal regulatory agencies tasked with the applicable responsibilities.

Do not ship any package containing a battery, biological, botanical, chemical or radioactive material without meeting the stringent packaging and training requirements of the Department of Transportation (DOT) or the Federal Aviation Administration (FAA), as required. The following offices/persons can assist you with package preparation and shipment(s):

- Biology / Neuroscience Safety Officer 413-542-8328

- Chemical Hygiene Officer 413-542-2736

- Environmental Health and Safety 413-542-8189

The following protocols are for Dry Ice (carbon dioxide) only. For the shipment of any hazardous material, including batteries and plants, the Amherst College IATA / DOT Policy shall be used.

Dry Ice / Carbon Dioxide (solid) shipped by itself or used as a refrigerant for other commodities;

- may be carried provide the operator has made suitable arrangements depending on the aircraft type

- the aircraft ventilation rates

- the methods of packaging and storing

- whether or not animals will be carried on the same flight and other associated factors

- The operator must inform staff that carbon dioxide (Dry Ice) is being loaded, or is on board the aircraft.

Follow the policies and procedures after you have received proper training.

- The procedures outlined in this guide are those that include no other hazardous materials - other than dry ice itself.

Requirements

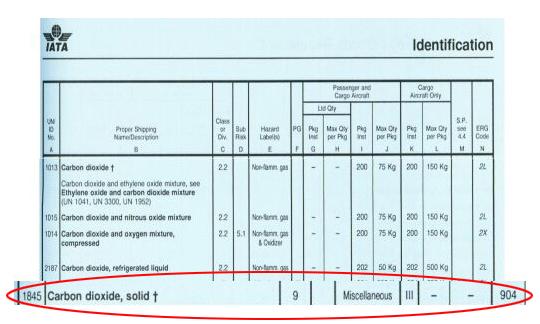

Several of these entries for carbon dioxide look similar. The correct one for Dry Ice is UN 1845 Class 9 Packing Group III. The Packing Instruction when filling out the Dangerous Goods Declaration is 904.

Dry Ice (carbon dioxide) when offered for transportation, that could or will involve air, must be in packaging designed and constructed to permit the release of carbon dioxide gas and to prevent a build up of pressure that could cause rupture of the package.

- The net weight in kg(s) of the Dry Ice (carbon dioxide) must be marked on the outside of the package.

- Gas venting: packages must allow for release of carbon dioxide gas. Dry ice must never be sealed in a container with an airtight seal such as a jar with a threaded lid or a plastic cooler.

- Package integrity: a package containing dry ice must be of adequate strength for intended use. It must be strong enough to withstand the loading and unloading normally encountered in transport. It must also be constructed and closed in order to prevent any loss of contents that might be caused by vibration or by changes in temperature, humidity, or altitude.

- Package materials: do not use plastics that can be rendered brittle or permeable by the temperature of dry ice. This problem can be avoided by using commercially available packages intended to contain Dry Ice (carbon dioxide).

- Inner Packaging Materials: depending on what is being shipped, containers, equipment, glass item(s), material etc... must be properly packed and/or secured in an outer, appropriate, durable material specific packaging in such a way that, under normal conditions of transport, they cannot break, be punctured or leak their contents into the outer packaging and so as to control their movement. Cushioning shall be used for breakable items. Any potential for leakage of contents must not substantially impair the protective properties of the cushioning material, or the outer packaging.

- Absorbent material cannot react with the contents of the container

- Dry Ice should not be placed in a pressure tight enclosure that would prohibit pressure relief.

- Absorbent material is not required if the inner packaging's are so protected that breakage of them and the leakage of their contents from the outer package will not occur during normal conditions of transport.

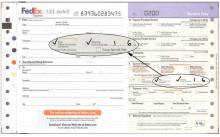

- Airbill: the airbill (also referred to as the air waybill) must include the statement “Dry ice, 9, UN1845, number of packages X net weight in kilograms.” FedEx has a check box on their airbill to satisfy this requirement; see Figure 2. Airborne Express requires a slightly different format; see Figure 3. Check with your courier to make sure you have made the proper notation on their paperwork.

- Labeling: the outermost container must be labeled with a hazard class 9 label, UN 1845, and net weight of Dry Ice in kilograms. See Figure 1. The label should be affixed to a vertical side of the box (not the top or bottom) and oriented as in Figure 1. The maximum allowable net quantity of dry ice allowed per package is 200 kg.

Additional Requirements for Preparing Your Dry Ice Shipments:

- DO fill any empty space in your package with appropriate packing material to prevent product movement in transit.

- DO wrap temperature sensitive products in two watertight plastic bags or use absorbent material along with a plastic liner.

- DO avoid shipping temperature sensitive products over the weekend.

- DO wrap the refrigerant in paper or another carton to slow the melting rate and prevent excess space when using dry ice.

- DO NOT place the refrigerant at the bottom of the package because cold air will not circulate.

Figure 1. Dry ice label.

Figure 2. FedEx Airbill. Highlighted area properly documents 1 box containing 6 kg of dry ice. (click to enlarge)

Figure 3. Airborne Express Airbill. Highlighted area shows format required for 1 box containing 5 kg of dry ice. (click to enlarge)

Hazard Classification / Identification

Dry ice is classified by DOT (Department of Transportation) and IATA (International Air Transport Association) as a “miscellaneous” hazard, class 9. Dry ice is considered hazardous during transportation for three reasons:

- Explosion hazard: dry ice releases a large volume of carbon dioxide gas as it sublimates. If packaged in a container that does not allow for release of the gas, it may explode, causing personal injury or property damage.

- Suffocation hazard: a large volume of carbon dioxide gas emitted in a confined space may create an oxygen deficient atmosphere.

- Contact hazard: dry ice is a cryogenic material that causes severe frostbite upon contact with skin.

Packaging Dry Ice properly will minimize the risk to personnel transporting the material. The explosion hazard will be eliminated with a package designed to vent gaseous carbon dioxide. Suffocation and contact hazards will be greatly reduced by labeling the package correctly, so those who come in contact with it will be aware of the contents.

Training Requirements

Federal Regulations state that anyone wishing to ship dry ice must first have IATA / DOT training. If you are going to package Dry Ice for shipment or sign any type of shipping documentation (such as a FedEx Airbill) for a Dry Ice shipment, you must follow the training certification requirements outlined below.

- Register / schedule training for IATA / DOT with Environmental Health and Safety.

- Read and review this guide. This guide will explain the general provisions relating to the regulations and detailed training in the requirements applicable to Dry Ice with no other hazardous materials.

- Submit to EH&S an

intent to ship dry ice form. EH&S will review this form with you and, upon successful completion, will certify you to ship dry ice.

intent to ship dry ice form. EH&S will review this form with you and, upon successful completion, will certify you to ship dry ice.

It is necessary to renew your certification every two years because of frequently changing rules and regulations. Training sessions reviewing this material are available from the Office of Environmental Health and Safety. Contact the EH&S at ehs@amherst.edu to schedule training or to ask questions regarding the shipment of Dry Ice (carbon dioxide).

Helpful Links

-

Acceptance Checklist for Dry Ice (Carbon Dioxide, solid) - Adobe Acrobat PDF

Acceptance Checklist for Dry Ice (Carbon Dioxide, solid) - Adobe Acrobat PDF -

IATA Dangerous Goods, January 2008 - Adobe Acrobat PDF

IATA Dangerous Goods, January 2008 - Adobe Acrobat PDF - PHMSA Response Letter

- Shipping Hazardous Materials

- Shipping of Dangerous Goods (Fed Ex)

- Title 49 Transportation

Additional Dry Ice Shipping Containers available at;

- All-Pak, Inc.

Corporate One West

1195 Washington Pike

Bridgeville, PA 15017

(800) 245-2283

http://www.all-pak.com - DG Supplies, Inc.

5 Boxal Drive

Cranbury, NJ 08512

(800) 347-7879

http://www.dgsupplies.com - Source Packaging of New England, Inc.

405 Kilvert Street

Warwick, RI 02886

(800) 200-0366

http://www.sourcepak.com